| Beschreibung: | Equispheres develops breakthrough technologies for the production and use of advanced materials in additive manufacturing. Leveraging our unique metal powders and process expertise, we are dedicated to driving forward the industrialization of additive manufacturing for the automotive, aerospace and defense industries. By lowering the cost and improving the performance of industrial 3D printing, we empower innovation.

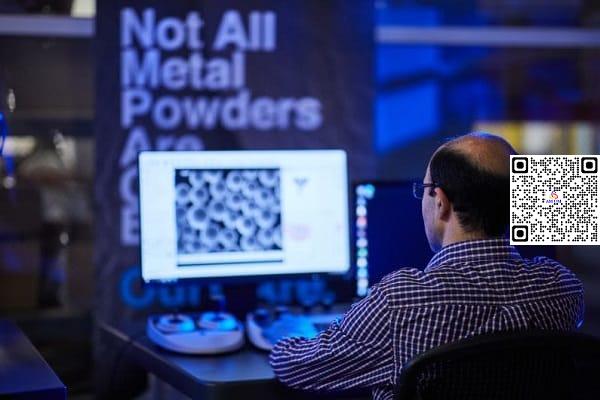

Equispheres’ breakthrough atomization technique produces a nearly-perfect powder. Its uniform size, sphericity, and consistent microstructure — as well as smoother surface and thinner oxide layer — result in more rapidly manufactured metal parts with superior mechanical properties.

Economic and Performance Advantages:

Increased design-allowable performance

Increase production speeds and lower costs

Equispheres proprietary powder lines

Powder Attributes:

Superior flowability and spreadability

Greater packing density and spread density

Thin oxide layers with less water adsorption

More uniform melt and solidification in every layer

Safety

Take advantage of our powder

Work closely with Applications Engineering support services to quickly transition from your current materials and fully benefit from the lower costs and superior performance our powder can offer. We offer starter packages to expedite the process of powder qualification and process optimization for your unique performance and production requirements.

Applications Engineering

Changing material suppliers or adopting a new alloy can be a daunting task. Validation and qualification of new powder take time and resources away from production. To simplify the transition and to ensure the success of your AM program, every purchase of Equispheres powder is supported by our professional Applications Engineering Services team.

The Equispheres Applications Engineering experts work with you to ensure a seamless transition. We draw on our broad testing database to help select the best print parameters to achieve your required part properties and production rates given your machine and process capabilities.

Learn more at Equispheres.com

What the future is made of.

|

English

English Chinesisch

Chinesisch Русский

Русский Español

Español

Die Liste der Kommentare ist leer.

Einen Kommentar hinterlassen